HVAC Refrigerants Explained: R-22, R-410A & What’s Next

The air conditioning systems in our homes rely heavily on refrigerants to cool and heat our living spaces. As we move forward, significant changes are on the horizon for the HVAC industry, particularly in the types of refrigerants used in newly manufactured products.

The evolution of refrigerants has been driven by environmental concerns, including their impact on the ozone layer and global warming potential. Older refrigerants like R-22 have been phased out due to their harmful effects, making way for more environmentally friendly alternatives like R-410A.

As the industry continues to adapt, understanding the role of refrigerants in your home’s heating and cooling systems is crucial. This guide will walk you through the changes and what they mean for you.

Key Takeaways

- Understanding the evolution of HVAC refrigerants and their environmental impact.

- Learning about the transition from older refrigerants like R-22 to newer ones.

- Discovering the upcoming changes in refrigerant regulations.

- Knowing how these changes might affect your current HVAC system.

- Getting insights into future HVAC purchases and refrigerant options.

Understanding HVAC Refrigerants and Their Role

Refrigerants are the backbone of cooling systems, enabling them to transfer heat from indoors to outdoors. An HVAC refrigerant, or AC refrigerant, is a substance that changes state from liquid to gas and back to liquid as it absorbs and releases heat, thus playing a critical role in cooling your home during the warmer months.

What Is a Refrigerant and How Does It Work?

A refrigerant is a specialized compound used in air conditioning and heat pump systems. It serves as the medium for heat transfer, absorbing heat from indoor air and releasing it outside. The unique properties of refrigerants allow them to change phase from liquid to gas and vice versa, facilitating the cooling process.

Refrigerants are designed to have low boiling points, which enables them to absorb heat from the indoor environment efficiently. As they absorb heat, they evaporate into a gas, which is then compressed and condensed back into a liquid, releasing the absorbed heat outside.

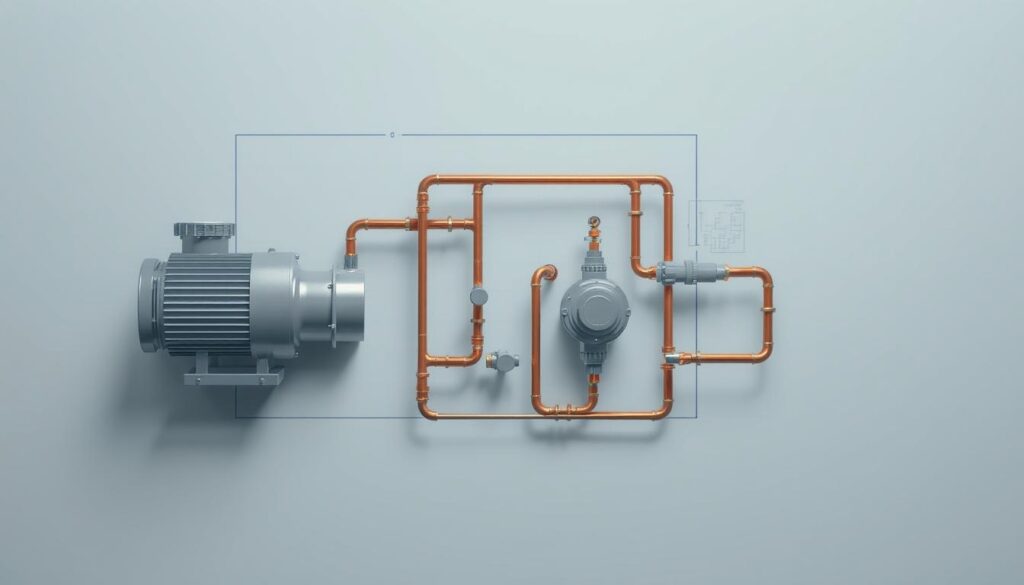

The Refrigeration Cycle Explained

The refrigeration cycle is a complex process involving four key stages: evaporation, compression, condensation, and expansion. In the evaporator coils, liquid refrigerant absorbs heat from the indoor air, cooling it before it’s circulated back into the living spaces.

As the refrigerant absorbs heat and changes to a gas, it travels to the compressor, where its temperature and pressure are increased. The hot, high-pressure gas then moves to the condenser, typically located in the outdoor unit, where it releases heat to the outside air and condenses back into a liquid. This continuous cycle is crucial for maintaining comfortable indoor temperatures.

| Stage | Process | Refrigerant State |

|---|---|---|

| Evaporation | Absorbs heat from indoor air | Liquid to Gas |

| Compression | Increases temperature and pressure | Gas |

| Condensation | Releases heat to outside air | Gas to Liquid |

| Expansion | Reduces pressure, allowing cooling | Liquid |

The Environmental Impact of Refrigerants

Understanding the environmental implications of refrigerants is essential for mitigating their harmful effects on the climate and ozone layer. Refrigerants have been a significant focus of environmental regulations due to their potential impact on both the ozone layer and global climate systems.

Global Warming Potential (GWP) Explained

Global Warming Potential (GWP) is a measure that compares how much heat a greenhouse gas traps in the atmosphere relative to carbon dioxide over a specific time period. Early refrigerants like CFCs and HCFCs had extremely high GWP values and also damaged the ozone layer, leading to international agreements to phase them out. For more information on the environmental impact of different HVAC refrigerants, visit Honeywell Air Comfort’s blog.

Ozone Depletion Potential (ODP) and Climate Change

Ozone Depletion Potential (ODP) measures a substance’s ability to break down ozone molecules in the upper atmosphere, which protects Earth from harmful ultraviolet radiation. The Montreal Protocol of 1987 was a landmark international agreement that established schedules for the phase-out of ozone-depleting substances, including many common refrigerants. As stated by environmental experts, “The phase-out of ozone-depleting substances has been a significant step towards protecting the ozone layer and mitigating climate change.”

Common HVAC Refrigerant Types Used in the US

The United States has witnessed multiple generations of HVAC refrigerants, each developed to improve performance or address environmental concerns.

R-22 (Freon): The Legacy Refrigerant

R-22 refrigerant, also known by the brand name Freon, is still in use in some older air conditioners and heat pumps manufactured before 2010. It’s a hydrochlorofluorocarbon (HCFC) that provided excellent cooling performance but was found to contribute significantly to ozone depletion and global warming.

R-410A: The Current Standard

R-410A is the R-22 refrigerant replacement that the HVAC industry transitioned to in AC units and heat pumps manufactured in 2010 and later. It’s a blend of hydrofluorocarbon (HFC) compounds R-32 and R-125, offering zero ozone depletion potential but still having a relatively high global warming potential.

Emerging Refrigerants: R-454B and R-32

The industry is now transitioning to newer options like R-454B and R-32, which offer significantly lower environmental impacts while maintaining efficient cooling performance. R-454B is a blend that many major manufacturers have selected as their preferred next-generation refrigerant for residential systems.

R-22 Refrigerant: History and Phase-Out

Understanding the history and phase-out of R-22 refrigerant is crucial for homeowners with older HVAC systems. R-22, commonly known as Freon, was the industry standard for decades before environmental concerns led to its phase-out.

Why Was R-22 Banned?

R-22 was classified as an HCFC (hydrochlorofluorocarbon) with significant ozone depletion potential and high global warming impact. The Montreal Protocol, an international treaty signed in 1987, established the framework for phasing out substances that deplete the ozone layer, including R-22.

The Montreal Protocol and HCFC Regulations

The United States committed to an international effort to regulate and phase out ozone-depleting substances with a high GWP such as R-22 when it joined countries worldwide to ratify the Montreal Protocol. In 2010, the U.S. ceased new production and importation of R-22 except for servicing existing HVAC units.

| Year | Regulation | Impact on R-22 |

|---|---|---|

| 1987 | Montreal Protocol Signed | Established framework for phasing out ozone-depleting substances |

| 2010 | U.S. Ceases New R-22 Production and Import | Except for servicing existing HVAC units |

| 2020 | Complete Ban on R-22 Production and Import | R-22 is no longer produced or imported into the United States |

What R-22 Phase-Out Means for Homeowners

For homeowners with older systems, this phase-out has significant implications, including rising costs for R-22 refrigerant as supplies dwindle. Systems manufactured before 2010 that use R-22 can still be serviced, but refrigerant costs have increased substantially, often making repairs less economical compared to system replacement.

R-410A Refrigerant: The Current Transition

With the introduction of the American Innovation & Manufacturing (AIM) Act, the phase-out of R-410A refrigerant has become a reality. R-410A is a blend of hydrofluorocarbon (HFC) compounds R-32 and R-125, and it has been the standard refrigerant for residential air conditioners and heat pumps manufactured after 2010.

Properties and Performance of R-410A

R-410A operates at higher pressures than R-22, requiring specially designed compressors and components in HVAC systems. It offers improved efficiency and zero ozone depletion potential. However, it still has a relatively high global warming potential (GWP) of approximately 2,088 times that of carbon dioxide.

The American Innovation & Manufacturing (AIM) Act

The AIM Act, passed in December 2020, gave the EPA authority to phase down HFCs like R-410A by 85% over the next 15 years. HVAC manufacturers have been preparing for this transition by developing and testing systems that use lower-GWP alternatives.

“The AIM Act represents a significant step towards reducing the environmental impact of refrigerants used in the HVAC industry.”

Timeline for R-410A Phase-Out

Under the EPA’s implementation plan, production and consumption of HFCs will be reduced in a stepped approach. The first major reduction occurs in 2024, and beginning January 1, 2025, new residential and light commercial air conditioning and heat pump equipment will no longer be permitted to use R-410A refrigerant.

| Year | Event |

|---|---|

| 2020 | AIM Act passed |

| 2024 | First major reduction in HFC production and consumption |

| 2025 | R-410A prohibited in new HVAC equipment |

For homeowners with R-410A systems, the phase-out doesn’t require immediate action, as existing equipment can continue to be serviced with R-410A for its useful life. Understanding this transition helps homeowners make informed decisions about the timing of system replacements and the types of refrigerants to consider for future purchases.

The Future of HVAC Refrigerants

With the phase-out of R-410A nearing, the HVAC industry is turning its attention to alternative refrigerants that offer lower global warming potential without compromising on performance.

As manufacturers and homeowners look to the future, two refrigerants have emerged as leading contenders to replace R-410A: R-454B and R-32.

R-454B: The Leading Replacement

R-454B is gaining traction as the preferred replacement for R-410A among major U.S. manufacturers.

This refrigerant is a blend of R-32, a hydrofluorocarbon (HFC), and R-1234yf, a hydrofluoroolefin (HFO), designed to balance energy efficiency, performance, and environmental sustainability.

With a global warming potential (GWP) of approximately 466, R-454B represents a significant reduction of about 78% compared to R-410A.

Its ability to offer similar cooling capacity and energy efficiency to R-410A, while requiring minimal changes to equipment design, makes it an attractive option for manufacturers.

R-32: Another Sustainable Alternative

R-32 is another promising refrigerant that has been widely adopted in other parts of the world, particularly in Asia and Europe.

As a single-component refrigerant, R-32 offers advantages in terms of system charging and potential for recycling.

With a GWP of approximately 675, it is about 68% lower than R-410A.

R-32 has demonstrated good performance in various climate conditions, making it a viable alternative for HVAC systems.

“The transition to lower-GWP refrigerants like R-454B and R-32 is a critical step in reducing the climate impact of cooling technologies,” as noted by industry experts.

What Homeowners Need to Know About Refrigerant Changes

As refrigerant regulations continue to evolve, homeowners are faced with important decisions about their HVAC systems. The key to making informed choices lies in understanding the current state of your system and the implications of refrigerant changes.

Do You Need to Replace Your Current System?

If you have an older central air conditioning system that uses R-22 (manufactured in 2009 or earlier), it’s nearing the end of its lifespan. While repairs are possible, considering replacement might be more cost-effective in the long run. For systems using R-410A and approaching 15 years of service, evaluating the need for replacement is also advisable.

Refrigerant Leaks and Proper Maintenance

Regular maintenance is crucial for preventing refrigerant leaks, which are harmful to the environment. If a leak occurs, prompt repair by a qualified technician is essential to prevent further damage and ensure the refrigerant is properly recovered.

Cost Implications of Refrigerant Transitions

The cost of transitioning to newer refrigerant technologies can vary. New systems using R-454B or R-32 may have different initial costs, but their long-term energy efficiency benefits can offset these differences. Additionally, some utility companies and government programs offer rebates for upgrading to more efficient HVAC systems.

| Refrigerant Type | System Age | Recommended Action |

|---|---|---|

| R-22 | Pre-2010 | Consider Replacement |

| R-410A | Approaching 15 years | Evaluate Replacement |

| R-454B/R-32 | New Installations | Consider Energy Efficiency Benefits |

Making Informed Decisions About Your HVAC System

As you navigate the evolving landscape of HVAC technology, making informed decisions about your system is crucial. Whether you need AC repair, are considering an air conditioner replacement, or are interested in a heat pump system, understanding the implications of refrigerant transitions is vital.

For systems less than 10 years old that are functioning well, regular maintenance is the best approach to maximize lifespan and efficiency. However, if your older system requires expensive repairs, especially involving refrigerant leaks, it may be time to consider upgrading to newer technology.

When replacing your system, discuss refrigerant options with your HVAC professional to understand the environmental impact and future serviceability of different choices. Consider the efficiency ratings (SEER, HSPF) of new systems, as higher efficiency units can significantly reduce energy consumption and operating costs.

Working with qualified HVAC professionals who stay current on refrigerant regulations and technology changes is essential for making sound long-term decisions about your home comfort systems. By considering factors such as the total cost of ownership and the global warming potential of different refrigerant options, you can make an informed decision that meets your needs and contributes to a more sustainable future.